The ultra-competitive nature modern day professional racing series requires an increased level of precision chassis setup. Advances in several areas, including chassis design, suspension theory and tire compounds, have drastically increased the level of achievable performance. Intercomp’s Precision Hub Plate Scale System controls the variables that impact a racecar’s setup.

Traditionally, racers measure corner weights with a wheel/tire set mounted and inflated to identical pressures to remove as many of the unknowns that could produce false readings. Depending on chassis sophistication, level of desired performance and other factors, tire pressure equalization may not produce satisfactory readings due to things like inconsistencies in wheels and tires.

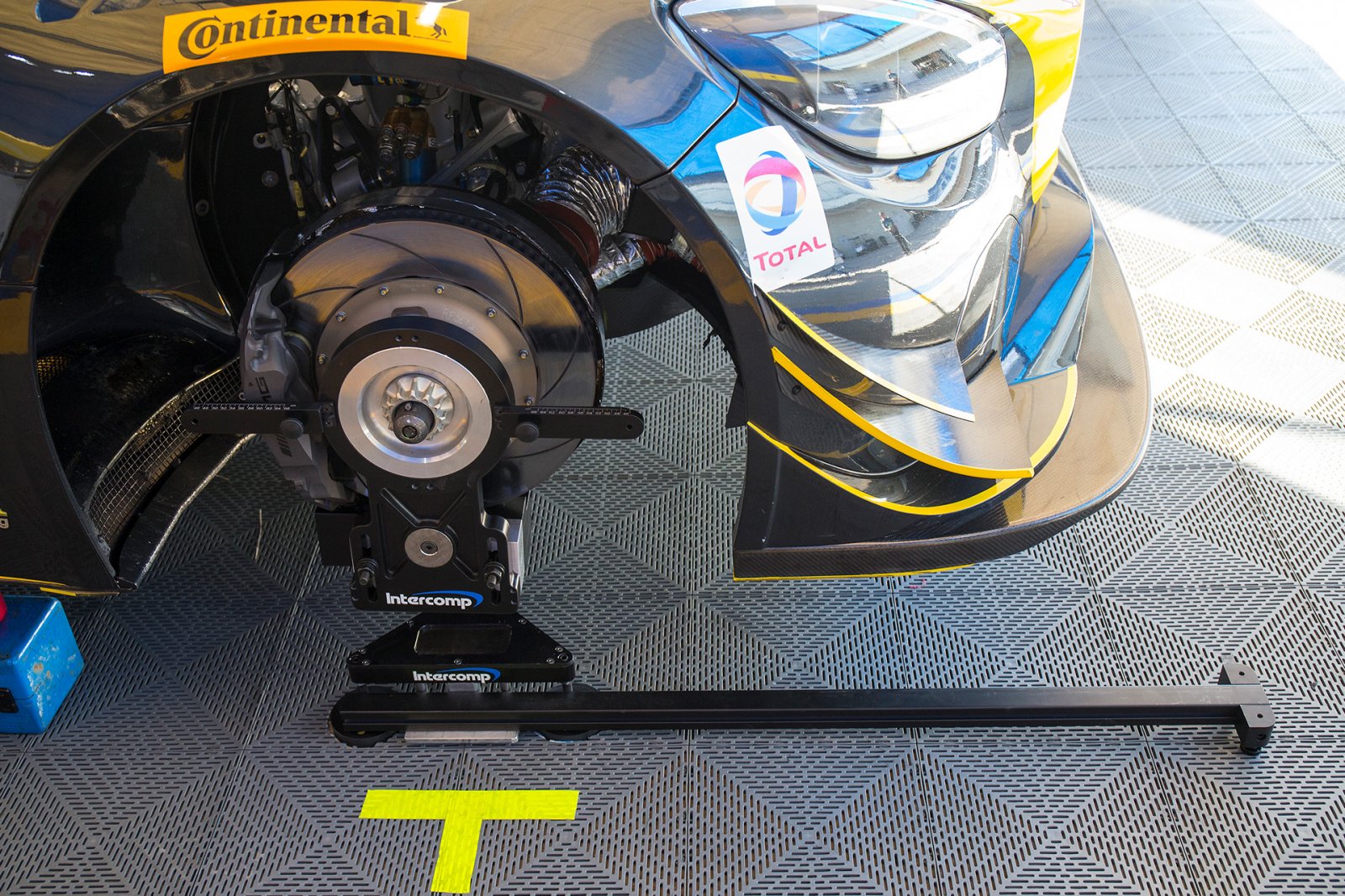

Many teams dedicate a single set of wheels and tires used only to obtain corner weights with a pad-type scale system, but that takes up additional space in an already packed transporter, garage or paddock space. Intercomp’s Hub Plate Scale System, the industry’s first alignment system with an integrated wireless scale in the hub stand, is the solution that allows for consistent scale values without the need for dedicated scale tires and wheels.

Hub stands for the system, made of 6061-T6 Aircraft-grade Billet Aluminum, pair superior materials and engineering with 360-Degree Ball Transfer Bearing Technology, which allows the suspension to settle without binding. Without mounted wheel/tire assemblies, mechanics can easily adjust chassis settings while suspension alignment is read with Intercomp’s Digital Caster/Camber Gauge attached to each hub stand using factory-installed steel inserts.

“Intercomp’s Hub Scale System has produced a more repeatable and precise result for us, when compared to a scale pad system,” said Lone Star Racing Team Manager AJ Peterson. The team has campaigned the No. 80 Mercedes-AMG GT3 in the IMSA (International Motor Sports Association) WeatherTech Championship and the Pirelli World Challenge series.

“The system is also compact and allows for easy transport and storage,” added Peterson when asked about additional benefits when competing in a national-level race series.

“The system is also compact and allows for easy transport and storage,” added Peterson when asked about additional benefits when competing in a national-level race series.

Built-in RFX technology increases the usability of the system with simultaneously displayed data on a wireless indicator or PC with RaceWeigh software. A variety of pre-made hub adaptors, including a blank adaptor that allows for custom machining for custom hubs, allow for flexibility in vehicle applications.